Integrates two independent braking mechanisms: an air-over-hydraulic disc brake for driving and an internal expanding drum brake for parking, ensuring safe and reliable operation.

A wide-opening rear engine hood allows quick access for maintenance and service, reducing downtime and improving efficiency.

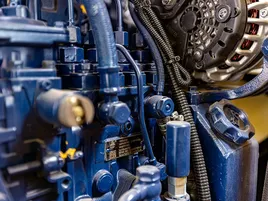

The vibration system features gear pumps and motors from PERMCO (USA), offering consistent performance and high efficiency under demanding conditions.

Fitted with a fully enclosed cab as standard, with optional heating and air conditioning to enhance operator comfort in any climate.

- Model GYS20J

- Operating weight 20000kg

- Vibratory drum diameter 1600mm

- Vibratory drum width 2130mm

- Vibratory frequency 30Hz

- Vibratory amplitude 2.0/1.0mm

- Centrifugal force 405/220kN

- Travel Speed (Forward) Ⅰ/Ⅱ/Ⅲ 2.5/5.0/10.5km/h

- Travel Speed (Reverse) Ⅰ/Ⅱ 2.5/5.0km/h

- Min. ground clearance 450mm

- Wheel base 3200mm

- Static line pressure 460N/cm

- Min. turning radius 6400mm

- Gradeability 30%

- Dimensions (L×W×H) 6240×2300×3080mm

- Engine model WP6G175

- Engine type Mechanical drive

- Power 129kW

- Rated speed 2000r/min

- Fuel tank capacity 300L

- Hydraulic oil tank capacity 190L

- Tire 20.5-25-16PR

SINOMACH has developed a global footprint, with marketing and service systems covering over 100 countries and regions.

Subsidiaries in West Africa, India, and South Africa, a joint venture in Malaysia, with offices in Mexico, Argentina, and the Philippines.

Supplied large-scale turnkey equipment packages including excavators, loaders, bulldozers, rollers, and graders for major infrastructure projects in Africa, mining operations in South America and the CIS, highways in West Africa, and engineering projects across Central Asia.

Operating weight 20000 kg

Operating weight 20000 kg Vibratory drum diameter 1600 mm

Vibratory drum diameter 1600 mm Centrifugal force 405/220 kN

Centrifugal force 405/220 kN