Powered by a 241 kW Cummins engine, this crawler excavator delivers strong performance under heavy loads while maintaining a low fuel consumption of just 236 g/kW·h.

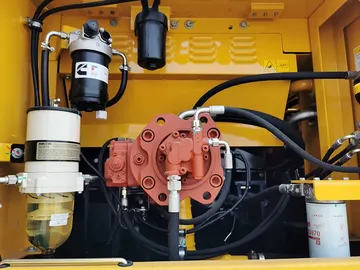

Equipped with a Kawasaki swing motor, the system ensures smoother combined operations through optimized flow distribution and reduced main valve pressure. Travel and swing systems maintain steady pressure levels of 34.3 MPa and 27 MPa respectively.

The integrated monitoring system provides real-time status updates, alerts for faults, and maintenance reminders to ensure long-term reliability.

Larger-diameter hydraulic cylinders and optimized pivot points enhance digging power. With an auto-boost function, the excavator reaches up to 225 kN bucket digging force and 182 kN arm digging force under heavy-duty conditions.

The reinforced box-section side beams and X-frame structure offer exceptional stability. Heavy-duty track rollers and carrier rollers help absorb high-impact loads in demanding environments.

A load-sensing hydraulic system ensures constant power output and efficient adaptation to different working scenarios.

Dimensions

- Operating weight 35000kg

- Rated bucket capacity 1.7m³

- Overall length 10921mm

- Overall width (standard track shoe) 3280mm

- Overall height 3546mm

- Turntable width 3060mm

- Cabin height 1000mm

- Ground clearance of counterweight 3512mm

- Engine cover height 2640mm

- Min. ground clearance 471mm

- Tail length 3405mm

- Turning radius of turnable 3450mm

- Wheel base of track shoe 4050mm

- Undercarriage length 4950mm

- Undercarriage width 3280mm

- Track shoe gauge 2680mm

- Standard track shoe width 600mm

Performance

- Max. traction 345kN

- Travelling speed (H/L) 4.7/2.5km/hr

- Swing speed 10rpm

- Gradeability 70%

- Ground pressure 0.619kgf/cm²

Working Range

- Max. digging radius 10233mm

- Max. digging radius at ground level 10028mm

- Max. digging depth 6536mm

- Max. digging depth at ground level 6331mm

- Max. vertical digging depth 4758mm

- Max. digging height 9617mm

- Max. dumping height 6666mm

- Min. front swing radius 4256mm

- Bucket digging force 225kN

- Stick digging force 182kN

Engine

- Model Cummins

- Type 6-cylinder in-line, four-stroke turbocharger

- Emission Tier Ⅱ

- Displacement 8.9L

- Rated power 241kW (325PS)@2000rpm

- Max. torque 1400N.m@1400rpm

SINOMACH has developed a global footprint, with marketing and service systems covering over 100 countries and regions.

Subsidiaries in West Africa, India, and South Africa, a joint venture in Malaysia, with offices in Mexico, Argentina, and the Philippines.

Supplied large-scale turnkey equipment packages including excavators, loaders, bulldozers, rollers, and graders for major infrastructure projects in Africa, mining operations in South America and the CIS, highways in West Africa, and engineering projects across Central Asia.

Operating weight 35000 kg

Operating weight 35000 kg  Rated bucket capacity 1.7 m³

Rated bucket capacity 1.7 m³  Overall length 10921 mm

Overall length 10921 mm