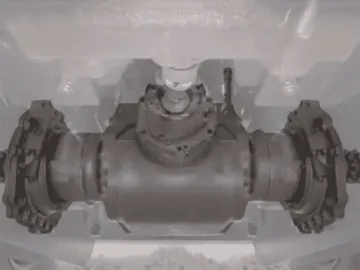

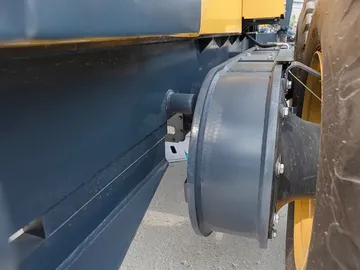

Equipped with a Komatsu-technology drive axle and a fully floating rear axle structure that enhances wheel installation stability and load distribution. This design reduces tire slippage and wear, improving traction and durability on rough terrain.

The flexible blade suspension system and articulated frame expand the working range, allowing for more efficient and precise grading.

The hydraulic system uses a single-pump oil supply configuration. Oil is distributed through a diverter valve to the left and right control valves, with local circuits reconverging afterward. This setup ensures a stable system pressure of 17.5 MPa while keeping overall flow low and minimizing energy loss, maintaining performance without compromising efficiency.

Equipped with heavy-duty dual-row roller chains built with an average breaking strength of 26 tons. This design eliminates the need for regular tension adjustments and easily handles the demands of harsh working conditions, effectively preventing chain breakage during high-load operations.

The blade/moldboard delivers a cutting depth of up to 535 mm and features a wide curvature adjustment range from 29° to 77°, making it highly efficient at turning over different types of soil. This allows for more professional and precise grading across various job sites.

The operator benefits from an unobstructed panoramic view and a suspended seat with headrest for added comfort. The cab can be optionally equipped with ROPS/FOPS for improved safety and features a comfortable interior with MP3/FM radio, high-power air conditioning (cooling and heating), and a USB charging port.

Overall Dimensions

- Length 8950mm

- Width 2600mm

- Height (to the top of the cab) 3420mm

- Wheel base 6100mm

- Track width 2120mm

- Min. turning radius 7.3m

Performance

- Operating weight 15600kg

- Blade length 4268mm

- Blade height 580mm

- Shovel blade thickness 20mm

- Max. lift above ground 450mm

- Max. grading depth 535mm

- Max. shoulder reach (outside of rear tires) 2400mm

Travel Speed

- Forward (1-6) 6.5/11.4/14.6/24.8/30/49.2km/h

- Reverse (1-3) 6.5/14.6/30km/h

Diesel Engine

- Model Dongfeng Cummins

- Type Direct injection, turbocharged, air to air cooling

- Rated output 142kW

- Rated speed 2200r/min

- Max. torque 860N.m@1400r/min

SINOMACH has developed a global footprint, with marketing and service systems covering over 100 countries and regions.

Subsidiaries in West Africa, India, and South Africa, a joint venture in Malaysia, with offices in Mexico, Argentina, and the Philippines.

Supplied large-scale turnkey equipment packages including excavators, loaders, bulldozers, rollers, and graders for major infrastructure projects in Africa, mining operations in South America and the CIS, highways in West Africa, and engineering projects across Central Asia.

Length 8950 mm

Length 8950 mm  Operating weight 15600 kg

Operating weight 15600 kg  Blade length 4268 mm

Blade length 4268 mm