The electric drive system combines a 200kW/1200N·m traction motor and a 140kW/350N·m hydraulic motor, operating independently for faster response, improved transmission efficiency, and up to 8 hours of runtime.

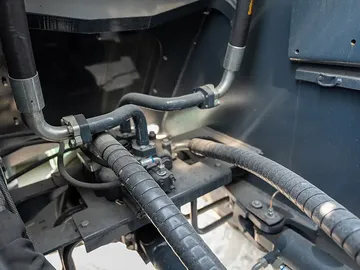

Patented enveloping coupling between the motor and transmission absorbs over 90% of vibration under demanding conditions, improving motor stability by 35%.

A dedicated cooling module with variable-speed electronic fans monitors motor and hydraulic oil temperature in real time, keeping oil temperature below 85 °C while reducing cooling energy consumption by 20%.

The integrated battery thermal control system maintains stable operation between –30 °C and 50 °C, extends battery life by 30%, and supports battery swapping for continuous uptime.

Four work modes are available; the intelligent control system adjusts torque output in real time, achieving fast cycle times with a 5.1 s lift and 1.3 s dump.

The high-voltage distribution unit (PDU) integrates insulation monitoring and electrical interlock features. Dual redundant braking options (dry or wet disc) and 12.4 MPa air pressure ensure top-tier safety.

- Rated load 5500kg

- Operating weight 18200kg (1±5%)

- Bucket capacity 2.7-4.5m³

- Max. dump clearance 3138-3663mm

- Lifting time 5.1s

- Descent time 3.6s

- Unloading time 1.3s

- Travel speed (F Ⅰ ) 0-13km/h

- Travel speed (F Ⅱ ) 0-39km/h

- Travel speed (R Ⅰ ) 0-13km/h

- Travel speed (R Ⅱ ) 0-39km/h

- Min. turning radius (over tire) 6371mm

- Gradeability 30°

- Max. traction force 164kN

- Max. lifting force 165kN

- Battery operating time (fully charged) 4-8h

- Length (with bucket on ground) 8710mm

- Width (to outside of wheels) 2821mm

- Height (to the top of the cab) 3537mm

- Bucket width 3048mm

- Wheel base 3420mm

- Track width 2226mm

- Min. ground clearance 450mm

Motor

- Torque Traveling motor 1200N.m, Service motor 350N.m

- Output Traveling motor 200kW, Service motor 140kW

- Speed 0-6000rpm

Transmission system

- Type Planetary electric shift

- Cooling method Oil-cooled pressure cycle

Tire

- Tire size 23.5-25-16PR

- Tire pressure 0.31±0.02MPa

Hydraulic system

- Type Twin pumps combined flow

- Lifting cylinder (number-diameter×stroke) 2-Ø160×810mm

- Unloading cylinder (number-diameter×stroke) 1-Ø180×563mm

- Max. working pressure 18MPa

Battery

- Battery type LFP

- Battery options 282kWh-EVE/CATL

- Battery options 350kWh-CATL

- Battery options 400kWh-Qiyuan Green Power

- Battery options Battery replaceable

SINOMACH has developed a global footprint, with marketing and service systems covering over 100 countries and regions.

Subsidiaries in West Africa, India, and South Africa, a joint venture in Malaysia, with offices in Mexico, Argentina, and the Philippines.

Supplied large-scale turnkey equipment packages including excavators, loaders, bulldozers, rollers, and graders for major infrastructure projects in Africa, mining operations in South America and the CIS, highways in West Africa, and engineering projects across Central Asia.

Bucket capacity 2.7-4.5m³

Bucket capacity 2.7-4.5m³  Length (with bucket on ground) 8710 mm

Length (with bucket on ground) 8710 mm  Max. lifting force 165 kN

Max. lifting force 165 kN